Supply chains are a cost center in many companies, but can be turned into a profit center if some effective practices are applied. In this blog, we will address some methods that can be used to turn supply chains into a profit center and it was a pleasure discussion with Abdullah Al Tassan who has four decades of experience.

Effective Practices to Turn the Cost Center into a Profit Center

1- Planning: Strategic and operational planning can be used accurately to reduce costs. Production can be increased to reduce the overall cost of the product, for example by increasing the number of products from 10 to 100, which is known as the Economy of Scale.

2- Supply: Strategic procurement and long-term framework agreements can be used to transform supply chains into a profit center. Strong relationships are built with suppliers, contractors, and business partners, based on transparency, trust, and mutual value. Strategic purchasing types, such as proactive buying or Forward buying, can also be used based on price fluctuations to keep costs stable.

Using these practices and examples, supply chains can be converted into a profit center rather than a cost center. Therefore, companies must work to implement effective and renewable business sustainability strategies to improve their performance and increase profits.

In the business world, supply chains are one of the most important areas that companies should pay much attention to, playing a pivotal role in generating profits and increasing productivity. In order to achieve this, supply chains must be converted into a profit center rather than a cost center.

3- Storage and warehouses: Inventory management can be improved to reduce costs associated with storage and disposal of excess inventory. The concept of Just in Time can also be used, where the product is brought in when needed rather than stored, reducing the costs associated with stores.

In addition, the costs associated with warehouses can be reduced by improving warehouse design and increasing warehouse automation. The concept of drainage purchase can also be used, where products are obtained when needed rather than purchased in bulk.

Two successful local examples in this regard are AL-Marai company and NUPCO, where AL-Marai has improved its supply chain to reduce costs associated with storage and inventory management and improve manufacturing processes using modern technology. NUPCO used the drainage procurement concept to improve supply operations and reduce associated costs.

4- Manufacturing: Modern technology and artificial intelligence can be used to improve manufacturing processes and reduce associated costs.

5- Logistics:

5-1 Consolidate Shipment Assembly Concept: Helps reduce the number of vehicles used in charging and improve the efficiency of operations. This technology involves collecting cargo in one car rather than using several vehicles, and reducing excess truck space.

5-2 The Reverse Logistics concept: helps reduce costs and improve efficiency in transfers and distributions. These include the use of empty trucks to move goods in the opposite direction, and reducing the number of vacant trips.

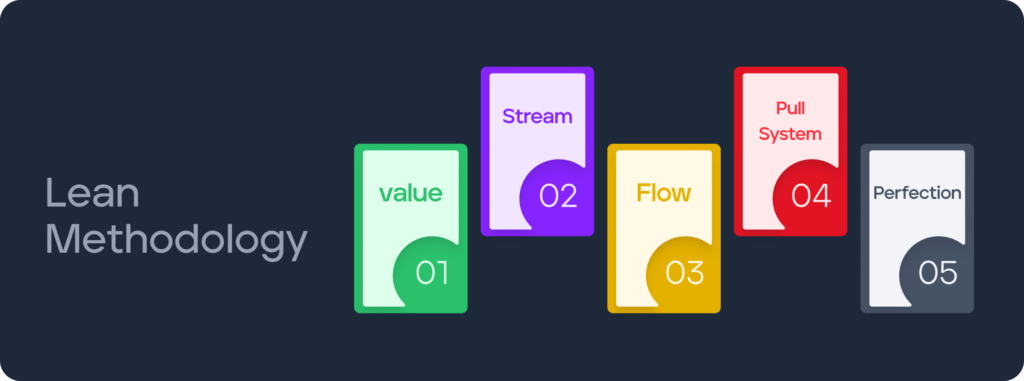

Lean Methodology

General points applicable to all five points is the use of Lean methodologies: Lean methodologies are an effective tool for improving supply chain operations, helping reduce waste, and improving process efficiency. These methodologies include improving production processes and removing unnecessary processes, resulting in reduced overhead production costs and increased profitability.

One question for you to think about:

How to make supply chains a profit center instead of a cost center?