Suppliers are more than just names on a PO—they’re the backbone of your operations.

Whether you’re sourcing raw materials, technology, or services, the quality of your suppliers can make or break your success. But here’s the challenge: how can you be sure your suppliers are performing at the level your business demands?

You can’t rely on assumptions. You need real data. That’s where supplier performance KPIs come in.These metrics help procurement leaders uncover blind spots, strengthen relationships, and build a supply chain that’s resilient, cost-effective, and compliant.

Let’s break down the 5 KPIs that matter most—and how to apply them to make smarter decisions.

What does it measure?

How quickly and comprehensively suppliers respond to RFx requests (including RFQs, RFPs, and RFIs). Slow or incomplete responses can stall procurement cycles and force rushed decisions.

By tracking RFx responsiveness, procurement teams can:

- Evaluate supplier engagement and reliability

- Shorten sourcing timelines

- Prioritize vendors who are aligned with your business pace and priorities

What does it measure?

The consistency and fairness of supplier pricing compared to internal benchmarks and historical data. This isn’t about pushing for the lowest price—it’s about ensuring fair value and transparency.

Monitoring this KPI helps you:

- Detect pricing trends and inconsistencies

- Strengthen cost control and budget accuracy

- Uncover opportunities for negotiation or re-sourcing

What does it measure?

The percentage of orders delivered by the promised date. Timely delivery is foundational to keeping your business running smoothly. Missed deadlines can lead to production delays, cost overruns, and customer dissatisfaction.

Tracking this KPI allows you to:

- Flag underperforming suppliers early

- Maintain operational flow

- Back your negotiations with real performance data

What does it measure?

The percentage of received goods or services that fail to meet quality standards. A shipment can arrive on time, but if it’s filled with defective or non-compliant items, your team still loses time and trust.

This KPI helps you:

- Spot recurring quality issues

- Collaborate with suppliers on corrective actions

- Protect your organization from costly rework or reputational damage

What does it measure?

Supplier adherence to legal, regulatory, and procedural requirements—such as valid certifications, contracts, and required documentation. Non-compliance can result in operational delays or legal exposure.

This KPI allows you to:

- Ensure readiness for audits and reviews

- Mitigate procurement risks

- Hold suppliers accountable to contractual terms

How to Track These KPIs Without Drowning in Data

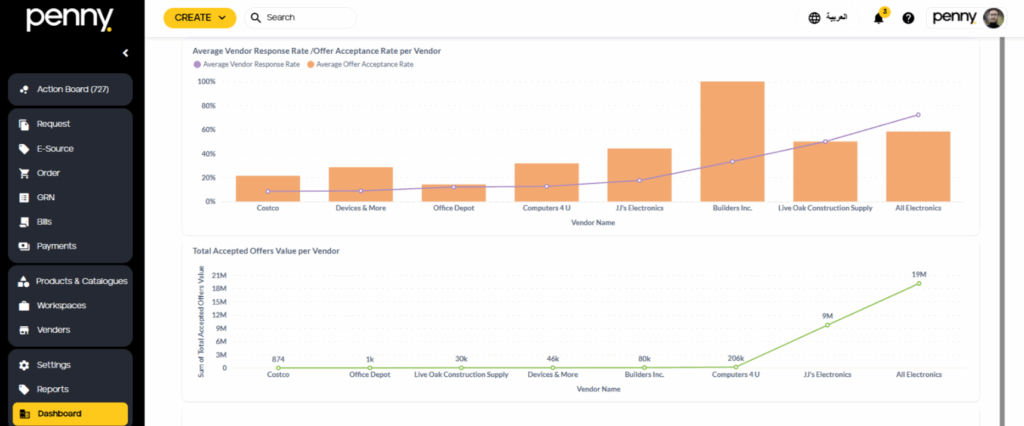

You don’t need a massive analytics team or a complex system to measure what matters—you just need the right tools. With Penny’s procurement technology, tracking supplier performance becomes seamless.

The platform gives procurement leaders the visibility they need through:

- Real-time dashboards

- Customizable supplier scorecards

- Automated tracking of RFx responsiveness, delivery rates, and more

Instead of chasing spreadsheets or scattered reports, Penny Analytics centralizes supplier performance insights in one place—making it easier to compare vendors, spot trends, and take data-driven actions that reduce risk and boost efficiency.

Penny empowers procurement teams to shift from reactive firefighting to strategic supplier management—so every decision is backed by clear, reliable data.

The key takeaway

Procurement is no longer just a cost center—it’s a strategic advantage. The most effective strategies are built on visibility, not assumptions. By tracking the right KPIs, you gain the insight needed to improve supplier performance, reduce risk, and make smarter, faster decisions.

You don’t need a complex system to get started. With the right metrics and tools, you can shift from reactive tasks to proactive strategy—driving transparency, governance, and long-term value across your supply chain.